Solutions for Groundcare & Turf-care

Applications in the Groundcare & Turf-care Sector

Electromagnetic clutches, brakes, and flexible couplings play a crucial role in enhancing the performance, safety, and efficiency of machinery used in the Groundcare & Turf-care sector. Here's how each component contributes:

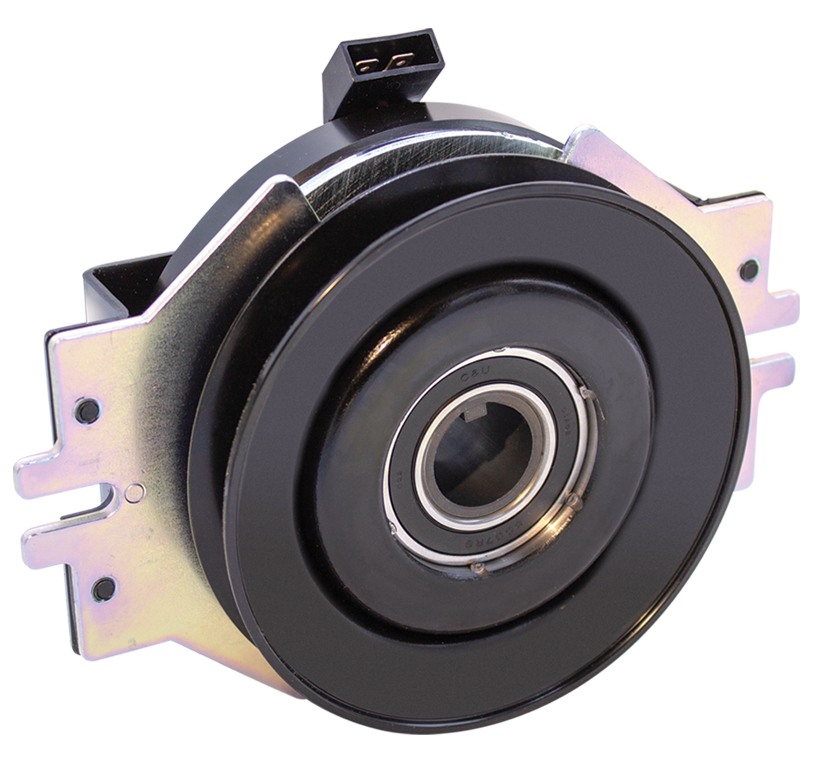

Electromagnetic Clutches

Function:

Enable or disengage power transmission from the engine to various implements or attachments on-demand.

Common Uses:

- Lawn mowers & ride-on mowers: Control the engagement of cutting decks and blades with precision.

- Aerators & dethatchers: Enable or disable rotating tines or blades without stopping the engine.

- Sweepers & vacuums: Allow selective activation of brush and suction mechanisms.

Electromagnetic Brakes

Function:

Provide controlled stopping or holding torque to rotating components, enhancing safety and operator control.

Common Uses:

- Slope mowers & bank mowers: Offer emergency braking and parking capabilities on inclines.

- Tractor-mounted attachments: Provide quick stop functionality for spinning or dangerous components like rotary brushes or tillers.

- Remote-controlled turf machines: Ensure precise stop/start functions, especially on sensitive terrain like golf courses.

Flexible Couplings

Function:

Transmit torque between shafts while compensating for misalignment and absorbing vibrations.

Common Uses:

- Mower decks and PTO shafts: Ensure smooth power transfer and protect against mechanical shock loads.

- Soil-preparation equipment: Reduce stress and wear on drive systems in rotary tillers and seeders.

- Irrigation systems: Maintain alignment and smooth rotation in pump drives.

Typical Groundcare & Turf-care Applications

- Ride-on mowers

- Aerators & dethatchers

- Tractor-mounted rotary brushes or tillers

- Remote controlled turf machines

- Sweepers & vacuums

Key Benefits for the Groundcare & Turf-care Sector

Improved Equipment Life:

Reduced shock loads and misalignment damage.

Enhanced Operator Safety:

Controlled and reliable braking systems.

Efficiency & Precision:

Quick, reliable power engagement/disengagement.

Lower Maintenance Downtime:

Fewer mechanical failures and easier servicing.

Looking for a tailored solution for your application?

Contact us to discuss your project needs.