Solutions for Agriculture

Applications in the Agricultural Sector

Electromagnetic clutches, brakes, and flexible couplings play essential roles in improving efficiency, safety, and durability across a wide range of agricultural machinery and equipment. Here’s how each component is typically used within the sector:

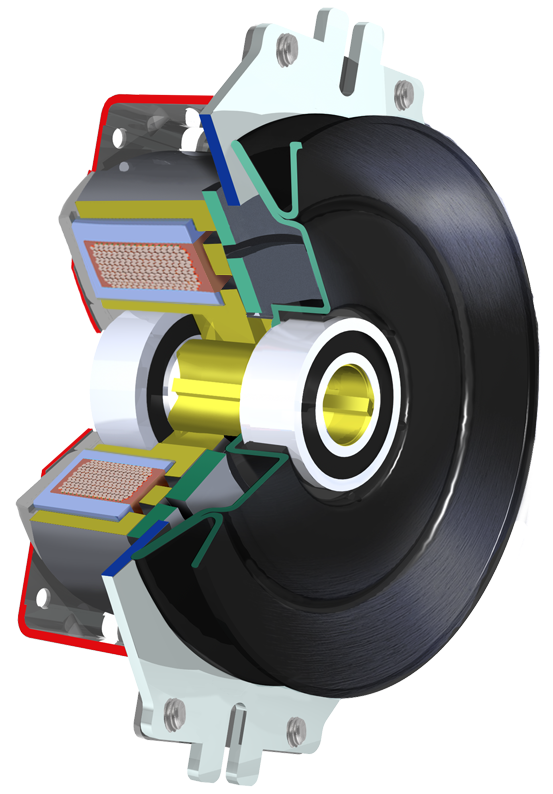

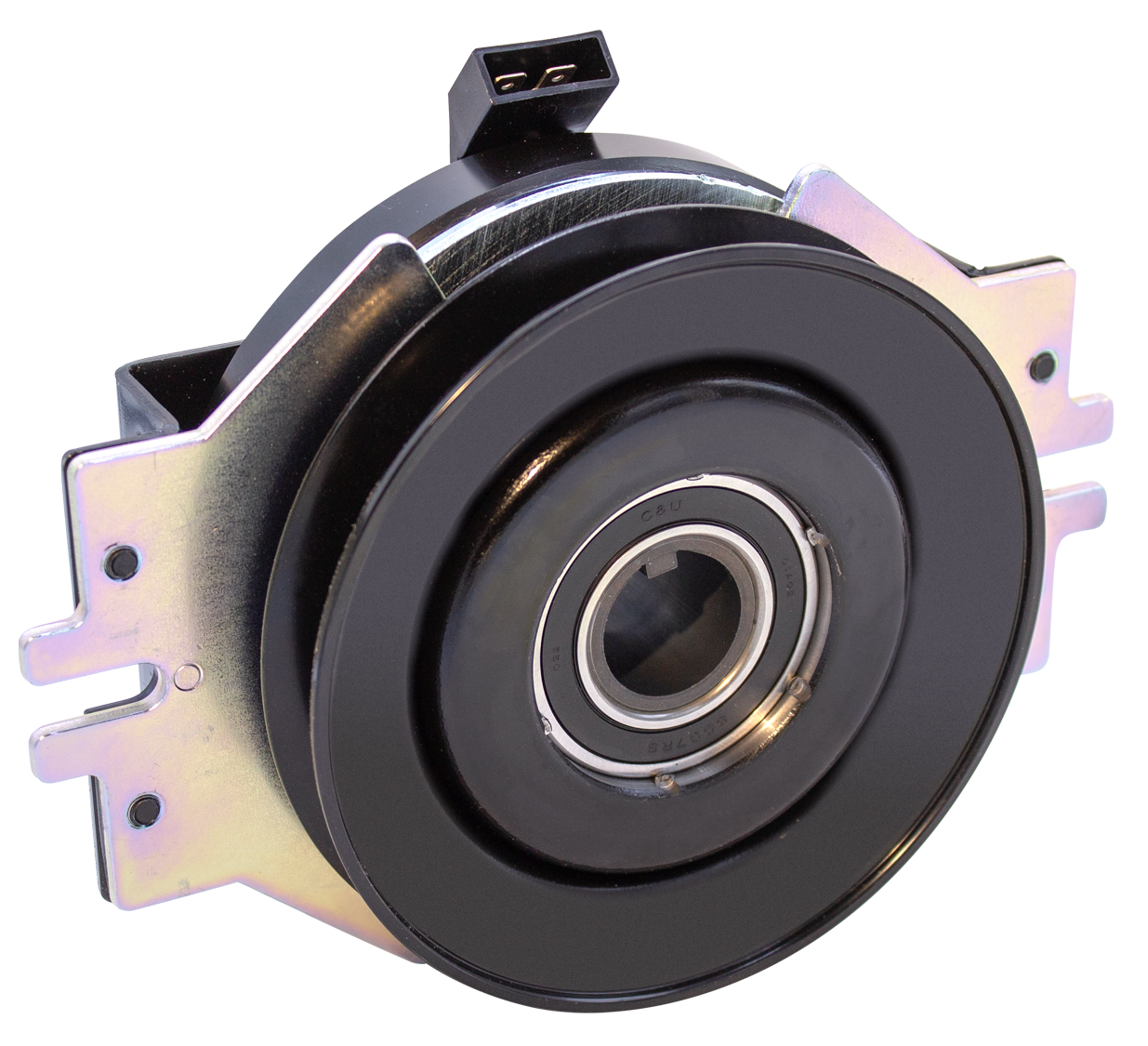

Electromagnetic Clutches

Function:

Engage/disengage power transmission from engine or motor to driven components.

Common Uses:

- Tractors & Harvesters: Control PTO (Power Take-Off) engagement for implements like mowers, balers, or augers.

- Sprayers & Seeders: Precise control over pump or agitator activation.

- Conveyors & Feed Systems: Enable intermittent operation without shutting down the main motor.

Benefits:

- Smooth engagement

- Remote and automated control

- Reduces wear compared to mechanical clutches

Electromagnetic Brakes

Function:

Stop or hold rotating components, especially in mobile or powered equipment.

Common Uses:

- Balers: Hold spindles or feed rollers in position.

- Harvesting Equipment: Stop blades or moving arms quickly for safety.

- Automated Farm Equipment (AGVs, Robotic Arms): Controlled stop positioning.

Benefits:

- Fail-safe operation (spring-applied, power-released)

- Quick reaction time

- Enhanced safety during emergency stops

Flexible Couplings

Function:

Transmit torque while accommodating misalignment and damping vibrations.

Common Uses:

- Pumps & Hydraulic Drives: Absorb shock loads and misalignment between pump and motor.

- Combine Harvesters, Augers: Protect drivetrain from shock loads during sudden crop blockages.

- Mobile Implements: Allow for shaft flexing during uneven terrain operation.

Benefits:

- Reduced maintenance costs

- Improved component lifespan

- Smoother power transmission

Key Machinery That Benefits

- Combine harvesters

- Tractors with front and rear PTO

- Irrigation systems

- Feed and grain handling conveyors

- Seeding, spraying, and fertilizing machines

- Autonomous guided vehicles (AGVs) in precision farming

Why These Solutions Matter in Agriculture

Automation-ready:

Easily integrated into automated systems for precision farming.

Reduced downtime:

Helps prevent mechanical failures in harsh field conditions.

Safety:

Ensures controlled, predictable machinery stops in case of emergency.

Looking for a tailored solution for your application?

Contact us to discuss your project needs.